Heron, founded in 1991, is a leading provider of innovative, sustainable resistance welding, clinching, and flush self-pierce riveting (FSPR) equipment. With proven expertise in hard-to-weld materials such as hot-stamped steel, high-strength steel, and aluminum alloys, we have steadily expanded our portfolio of high-quality welding solutions to meet global industry needs. Our resistance welding machines include MFDC spot & projection welders, CD spot & projection welders, AC spot & projection welders, seam welders, and butt welders. When it comes to metal joining technology, Heron is your trusted partner for advanced and customized solutions.

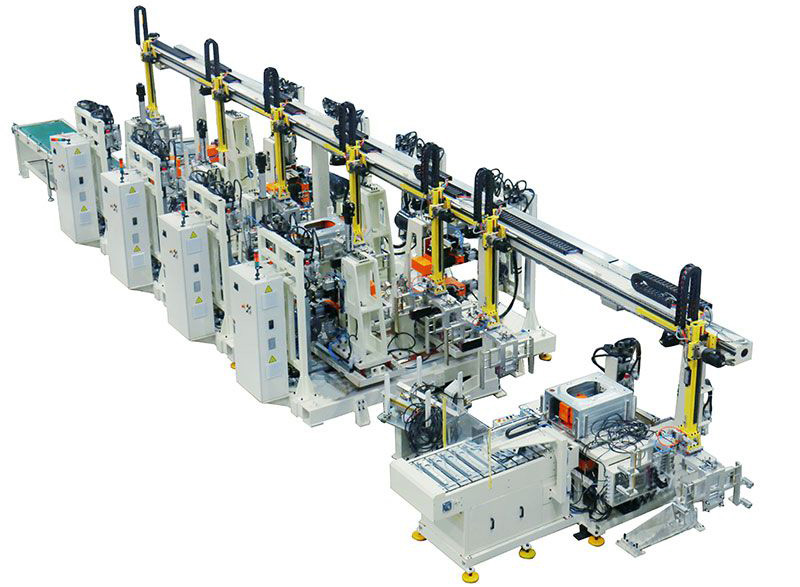

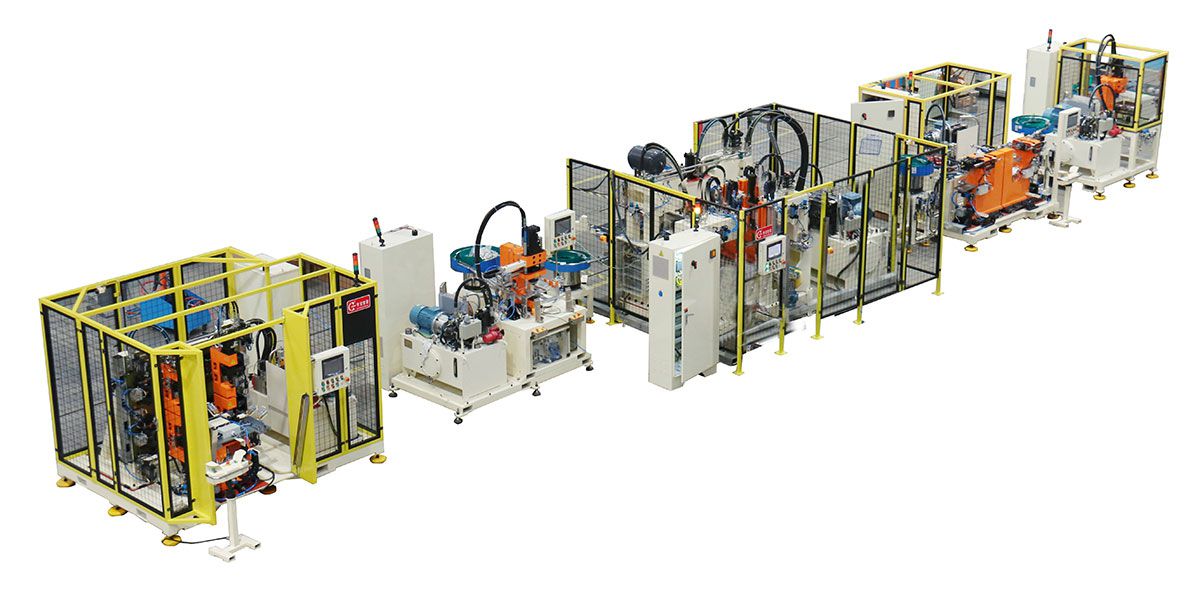

With HERON's self-developed resistance welding technology and riveting technology, modern automation mechanism and control principle, we offer automatic production lines for various industries, which reduces labor intensity. Along with intelligent manufacturing technology, complete stamping, forming, welding and riveting solutions are offered.

Clinching technique is applied for the line, which realizes complete processes including folding, assembling, riveting and transplanting.

Clinching technique is applied for the line, which realizes complete processes including folding, assembling, riveting and transplanting.

We offer fully automatic production line for refrigerator compressor lower shell welding processes. With resistance welding technique, copper tube and steel shell are joined together during the process. HERON’s medium frequency power supply is applied in the production line, which is energy saving and eco-friendly.

Our new technique is applied instead of traditional brazing process for tank furnace, which no longer consumes brazing material and continuous fuel burning, eco-friendly and cost-effective.

Over the past three decades, Heron has delivered a wide range of resistance welding machines to manufacturers worldwide. Our advanced welding equipment and automation systems have become indispensable in industries such as automotive, compressors, low-voltage electronics, home appliances, and a variety of consumer products. Tell us your specific requirements for welding or other joining technologies, and we will provide the right solution.

Heron provides manufacturers with auto parts welding machines that include a wide range of specialized welding equipment. Some of these products include spot and projection welding machines, recliner welding machines, nut welding equipment, car door welding machines, and more.

Heron provides motor manufacturers with high quality resistance welding machines for the production of their engine motors and alternators. The car alternator welders and engine motor welding machines are carefully designed to optimize production effectiveness and efficiency.

Heron provides high quality welding systems and that extends to our line of air compressor welding solutions. This resistance welding equipment covers equipment designed to process air compressor machines and reduce labor costs and maximize working efficiency.

Heron provides electrical resistance welding machines for the production of low voltage electronics. The machines can perform several functions, including multi-station automatic indexing, automatic feeding, and welding in order to realize fully automatic production.

This series of products covers our Home Appliance Welding Solutions. They feature capacitor discharge welding technology and improve the overall production efficiency of welding processes with consistency. The welding quality is also unparalleled.

The welding machine was originally designed for the group welding process of Snap-On tool boxes. The welder features a double station tooling system and combines robotic welding heads with traditional specifications to produce high quality products with efficiency.